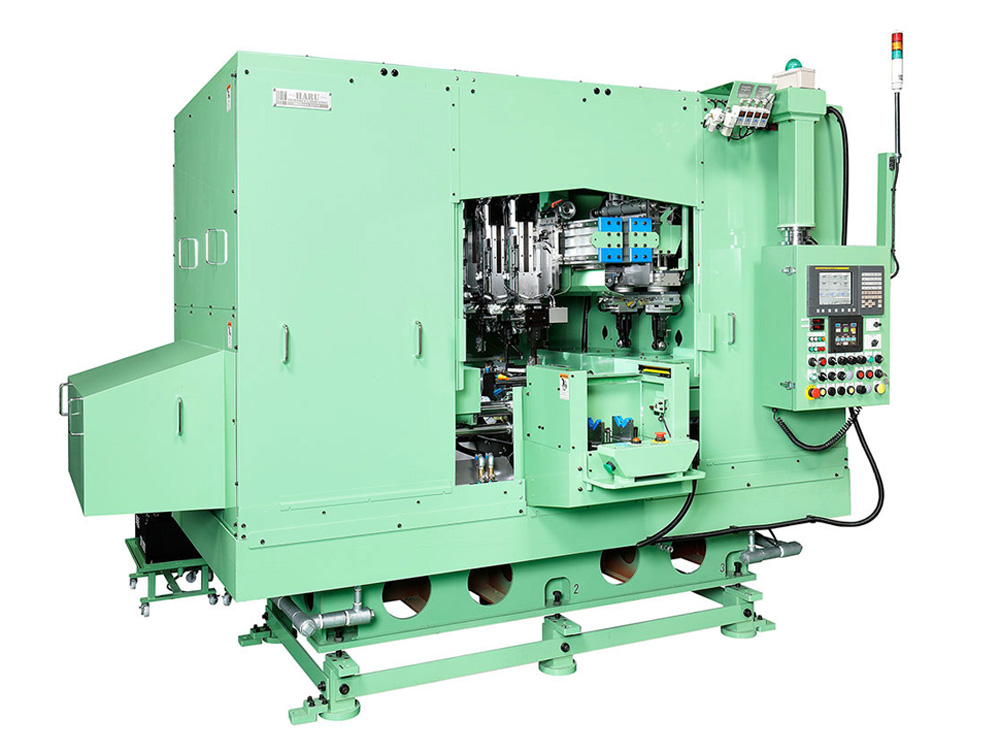

Diff Spherical Surface and End Face Cutting Machine WDM12B-4ATT

4 mounted spindles. Processing of the sphere and the end faces of the internal diff is possible with this machine. Faster, more accurate, and space-saving. Compatible with various factory line layouts.

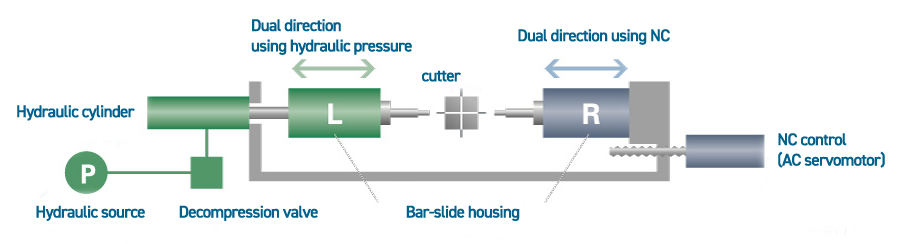

Reliable Bar Slide Spindle Structure

Bar slide structure without LM guide or box slide.It is resistant to the chronological thermal displacement, maintains high durability and vibration resistance, and provides high accuracy.Cp ? 1.66 or higher as a comprehensive product finish accuracy.

The bar slide has a wider pressure area than the box slide. This means that it is effective in all directions leading to higher rigidity and greater durability. The highly reliable bar slide will remain operational for 15-20 years.

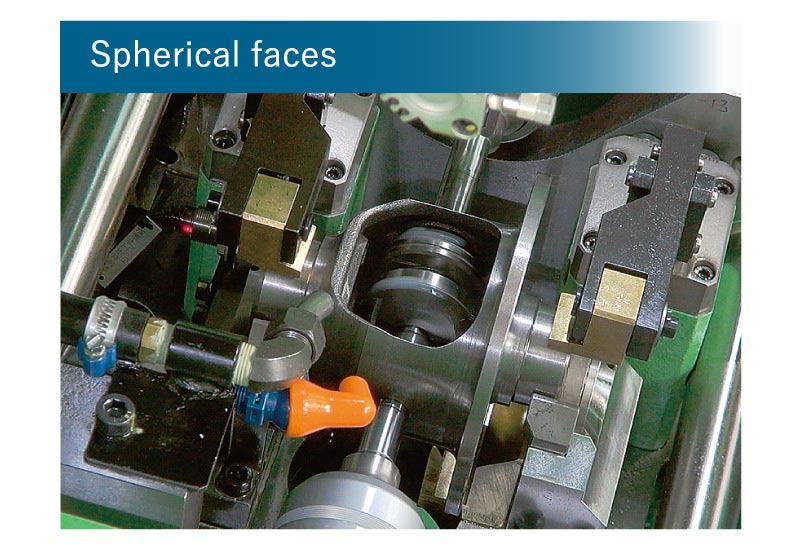

The left housing advances using hydraulic pressure and holds the cutter pressed against the right housing at a constant pressure. R-side servos precisely positions and performs an interlocking processes.

Equipped with four tool pickers

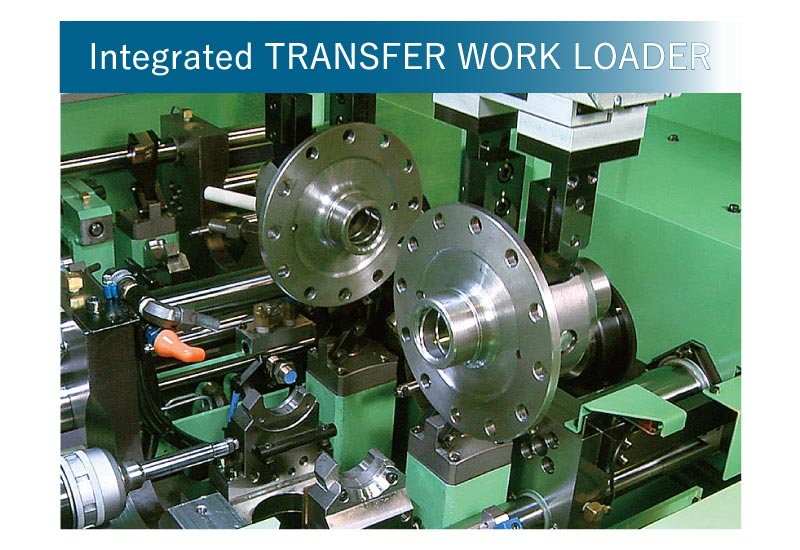

Transfer Type Work loader

Conveyed into the machine by two upper pickers.

Excellent Jig Characteristics

Quick stage change is made possible by the exchange of u-pad and mandrel.

The air-zero U-pad Sitting Detecting Device of the workpiece.

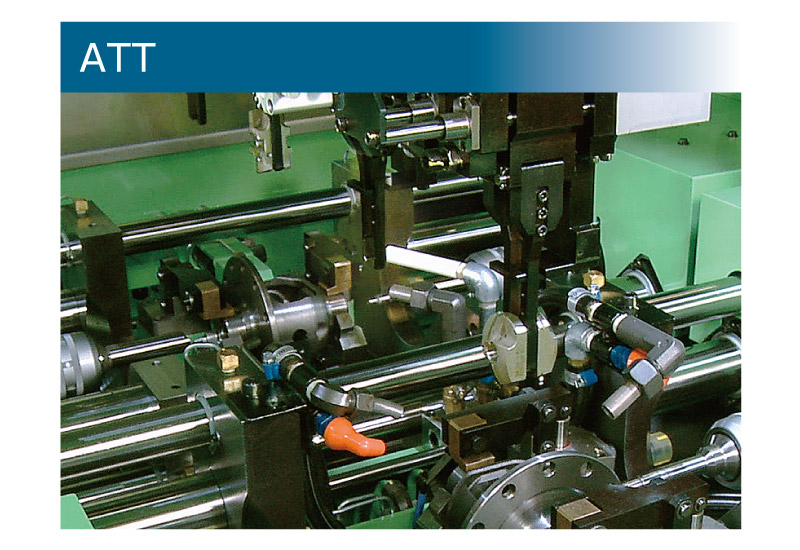

ATT(4 Tool Pickers)

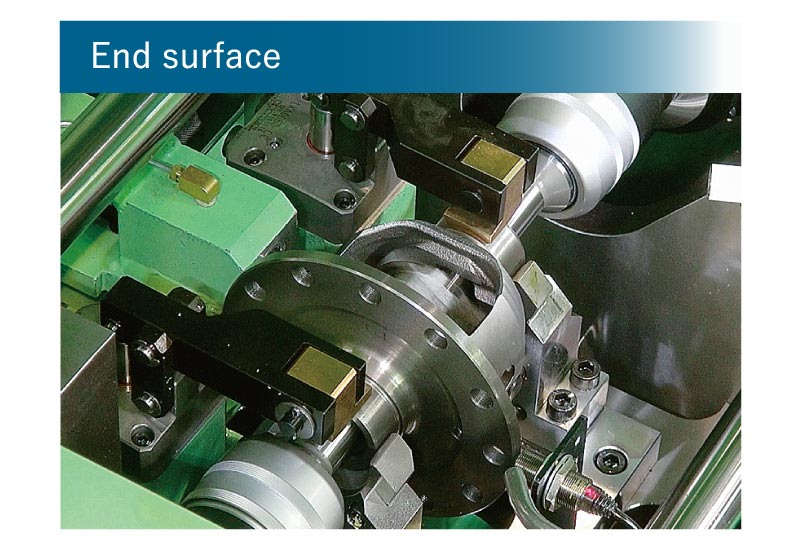

Up to 4 spherical/end face cutters can be mounted for different levels of finishing.

The rear door makes it easy to access from behind.

High speed, high accuracy, high quality machining

NC simultaneous processing of spherical/end face by 4 spindles. Reduces surface roughness by center-through. Prevention of defect outflow by dust contamination detection. Guaranteed machining accuracy by scale.

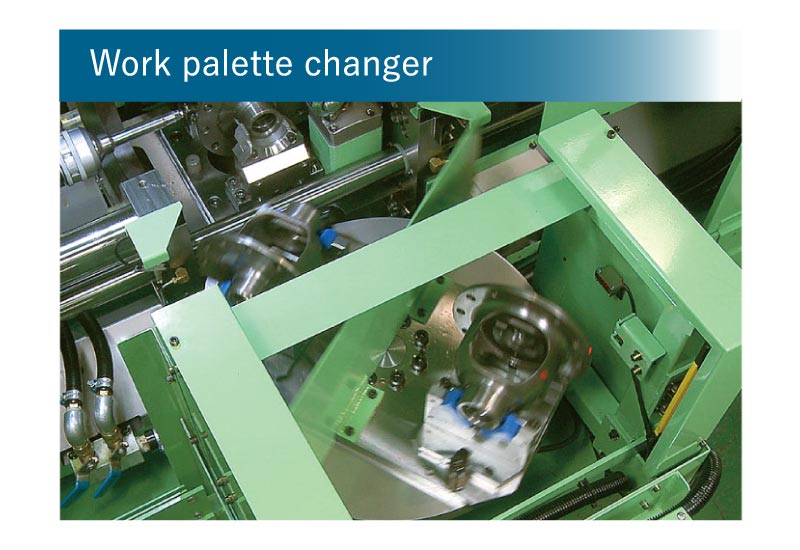

High Equipment Utilization Rate

The work pallet changer allows processing reservation for the following workpieces.

| Fanuc System |

NC-Control device | FANUC 35i |

|---|---|---|

| Four spindle | Spindle motor Spindle speed |

1/3 4P 1.5KW / 300-600 (rpm) |

| Size / Tool | Inside diameter ø60 BT-40 (Rear manual retraction) |

|

| Position stop device | Mechanical notch | |

| ATT | Spherical surface cutter feed device | Up / down : Air cylinder |

| Tool storage | Random pot type (16 tools) |

|

| End surface cutter feed device | U axis Fanuc B 4S 4000 0.75Kw | |

| Trasfer workloader | 90° turn two picker | Up / down : Air cylinder |

| Tool / Picker change | V axis Fanuc B 4S 4000 0.75Kw W axis Fanuc B 8is 3000 1.2Kw |

|

| Size/Weight | 3,090mm (W) x 2,090mm(D) x 2,200mm (H) / 4,500 kg |

| Axis | Stroke | Feed | Drive unit |

|---|---|---|---|

| Main”X”axis (Right unit) | 200mm | 5,000 (mm/min) | β 4is/4000 0.75Kw |

| Sub “X”axis (Left unit) | 350mm | ø63 Hydraulic cylinder | |

| Index Axis | F19.5mm+R90mm | 20min~1/min | βis8/3000 1.2kW |