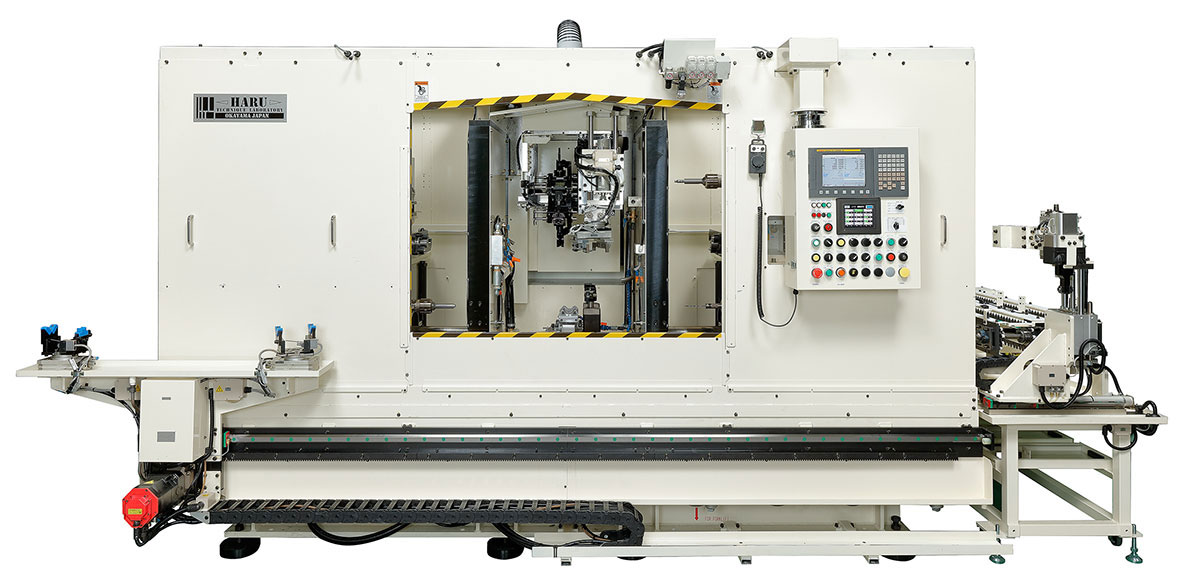

Diff Case Multitask Machining Center WDM40-DA16

A compact single machine delivers space-saving, short throughput, high machining accuracy and production efficiency. Equipped with ATC. Up to 11 types of differential case processing are possible in one unit.

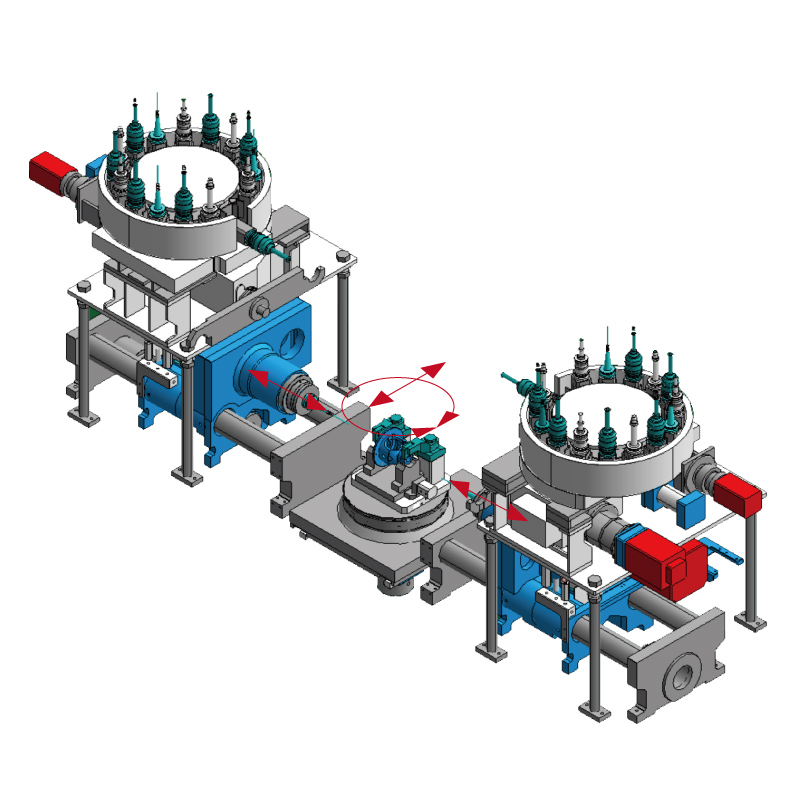

Excellent Jig configuration

Can be changed in three minutes.

Workpiece mounting position: 400mm.

Compatible with 660-4000cc differentials simply by replacing jigs.

Fixed Type left and right facing spindle

High rate of accuracy guaranteed.

Precise ATT control

4-axis NC control of X/Y/Z rotation allows spherical/end face cutters to be inserted into even the smallest of workpieces.

Tool magazine on the left and right

Each of the 16 BT40 tools (with ATC) is installed on the left and right. Tool replacement in two seconds.

Loading options

Workstockers, robots, internal loaders, external machine loaders

| FANUC SYSTEM |

Spindle | Right/Left-16bh |

|---|---|---|

| NC-Control device | FANUC 31i | |

| Spindle motor | FANUC βilP12/6000 5.5/7.5kW | |

| Spindle speed | 6000 min | |

| Spindle taper | BT-40 Spindle nose taper | |

| ATC | Type | Double-arm type |

| Tool storage | Random pot type (16 tools) |

|

| Tool Change time Too-Tool | 2.5 sec | |

| ATT | Cutter loading/unloading time | 11 sec |

| Weight | 6500kg | |

| Size | 3350mm(W)×2410(D)×2200(H) | |

| AXIS | STROKE | FEED | FANUC servo motor |

|---|---|---|---|

| X(R/L)AXIS | 590mm | 14m/min | βis12/2000 1.4kW |

| YAXIS | F19.5mm+R90mm | 18m/min | βis8/3000 1.2kW |

| Index AXIS | F19.5mm+R90mm | 20min-1/min | βis8/3000 1.2kW |