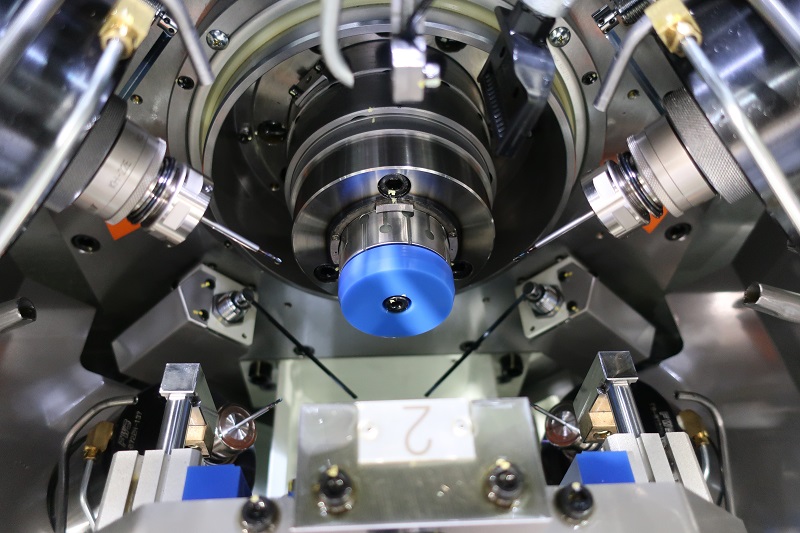

Circumferential 4-direction automatic drilling machine HFD-4

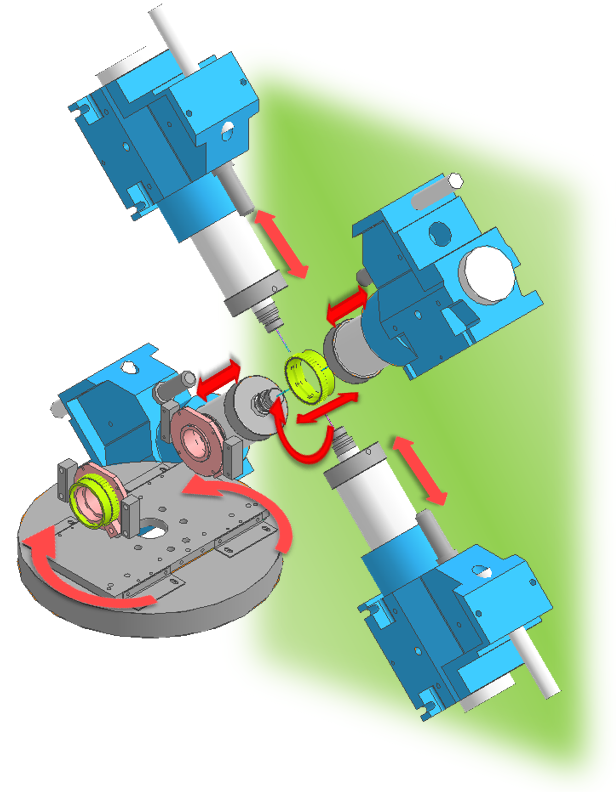

Simultaneous machining of cylindrical work from 4 directions

Machining time can be significantly shortened compared to the method

of machining multiple machines side by side.

Z, A, X 3-axis NC control

The depth of the hole, the direction of rotation, and the position

in the front-back direction can be easily changed.

It can also be used for workpieces with different outer diameter,

total length, and thickness.

A wide variety of options to meet your needs

Gear tooth and hole phase required. → Workpiece phase detection displacement sensor.

Want to automate using a robot, etc. → Turntable.

Worried about defective outflow. → Seating detection, drill breakage detection, external stage change box.

| FANUC SYSTEM |

NC-Control device | FANUC 31i |

|---|---|---|

| FOUR Spindle | Spindle motor | 200V 2P 0.4kW |

| Spindle Speed | Max 8000 rpm | |

| OTHERS | Work position height | 1000mm |

| Work size | Dia φ100~250 Dep max 110mm |

|

| Tool size | φ1.0~8.0 | |

| Weight | 4500kg | |

| Size | 1990mm(W)×2300(D)×2200(H) | |

| AXIS | STROKE | FEED | FANUC servo Motor |

|---|---|---|---|

| Z AXIS | 120mm | 8.0m/min | β4/4000is 0.75kW |

| X AXIS | 110mm | 5.0m/min | β8/3000is 1.2kW |

| A AXIS | 360°rotation | 4.0m/min | β8/3000is 1.2kW |