FACING UNITS

Facing Units

Dedicated Facing Machinery

NFC

Responding to Difficult Work

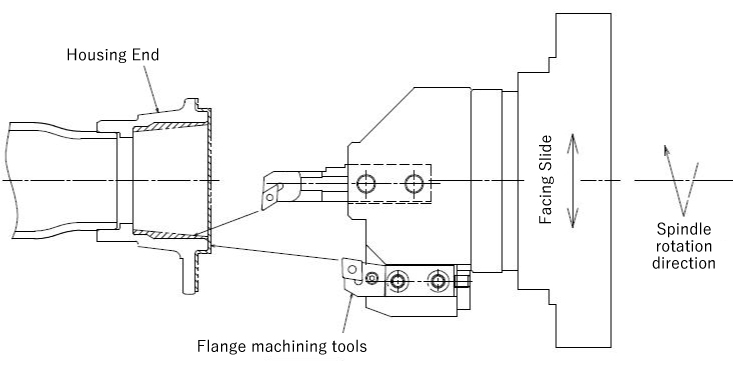

When clamping is difficult in the lathe chuck due to workpiece size and shape, or when contouring (arc cutting) by machining center is not allowed (e.g., to ensure airtightness in metal contacts, when the same feed is required as turning), face processing (which rotates and moves the blade without rotating the workpiece) is best.

A Wide Ranging Line-Up

We consistently offer dedicated machines with facing functions from concept to launch. It’s for the end users (engineering machinery division) who assemble dedicated machines in-house.

Options

Our facing machines have a variety of options. We can design exclusively according to your needs.

Image of The Facing

Simple image diagram of Facing Processing.

<Note:On the left is a workpiece. On the right is a tooling attached to the facing.>

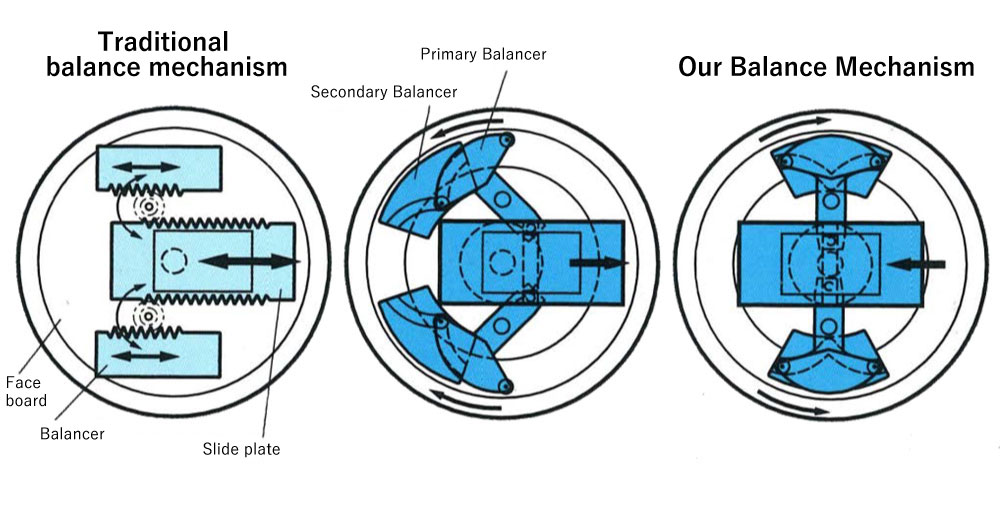

Our facing technology has three features:

1.High rotation and low vibration in all stroke areas

Our facing technology has a balance mechanism (the first and second). The use of this balance mechanism suppresses vibration at high rotation and increases machining accuracy.

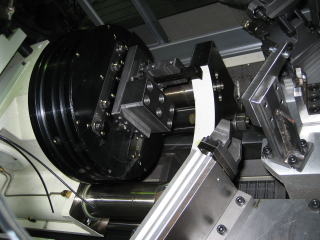

2. High rigidity and high cutting performance by truncated overhang

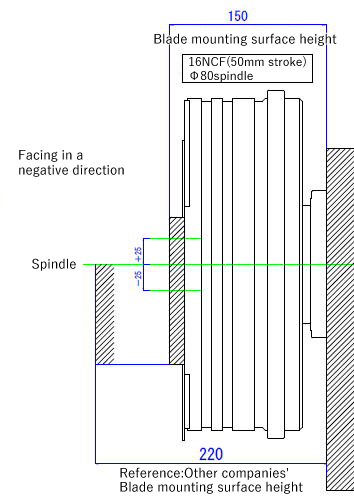

Our facing technology is designed to be as short as possible in distance (overhang) from the main shaft of the machine, to the blade mounting table (= slide) in comparison with other companies’ facing units. (See figure on the right)

This improves mechanical rigidity then improves finish accuracy and surface roughness.

The stroke 50mm on the right is an example. Select hydraulic pressure (18,40mm) and NC (50,75,100mm)

3. Accuracy and durability…Maintaining high accuracy even after heavy use over many years

1. Hard – wearing resistance is made possible by combining a high – durability, abrasion resistant, sliding surface material (epoxy resin) with hardened/polished slides. In addition, it has a more durable iron-cast system and maintains high accuracy even after heavy use over many years.

2.Avoiding Stick-Slip Phenomenon

The characteristics of the sliding surface material (epoxy resin) helps to avoid the ‘stick slip’ phenomenon that occurs on the sliding surface during linear and rotational motion. This is because the coefficient of static friction of the sliding surface material increases as the speed increases.

(coefficient of static friction < coefficient of dynamic friction)

This characteristic produces positive results in product accuracy at the time of micro-cutting feed.

【Photo on the upper right】A hardened/polished slide.

【Photo on the bottom right】An image. It is not a sliding infill material for actual facing.

Examples of Workpieces Suitable for Facing

There is such things as the appropriate workpieces.

|

|

|

|

| Auto Parts: Water Pump |

Auto Parts: Rear Axle Housing |

Plant parts: Valve |

Water Meter |

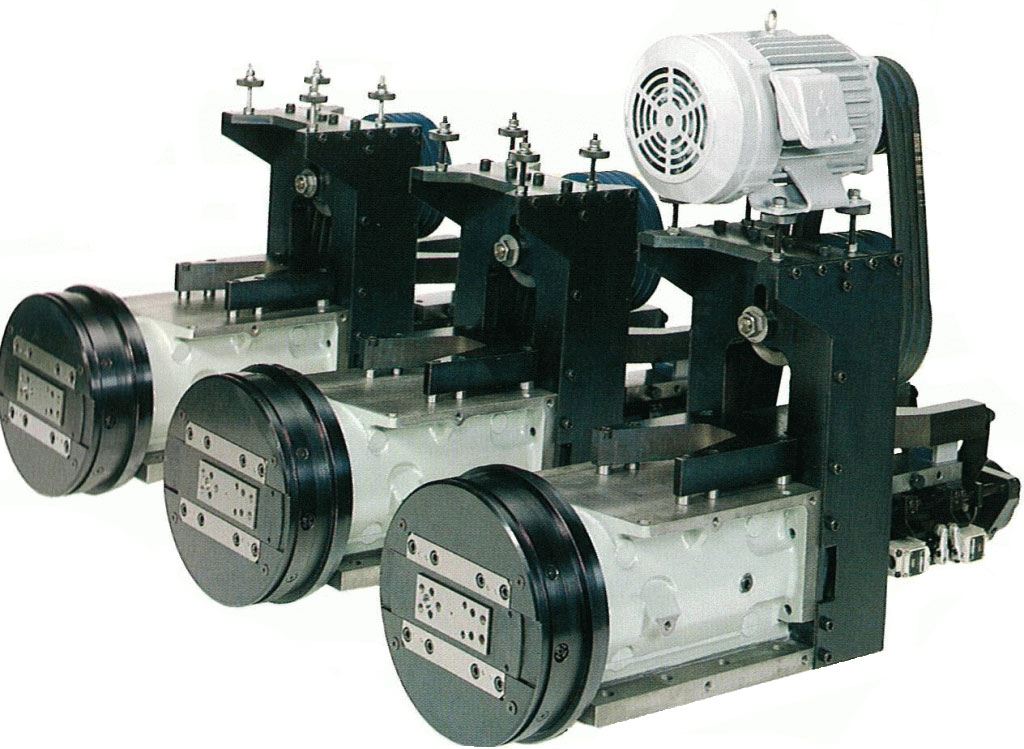

About Selling Facing Units Alone

We sell facing units installed in our cutting machine alone. This is for the end users (engineering machinery division) who assemble dedicated machines in-house.

●As a facing method, both NC facing and hydraulic facing are available in our lineup.

●Strokes are available in hydraulic pressure (18,40mm) and NC (50,75,100mm).

●For 16-Facing (16RF and 16NCF), you can choose from two types: “with Z-axis” (bar slide type) or “without Z-axis”.